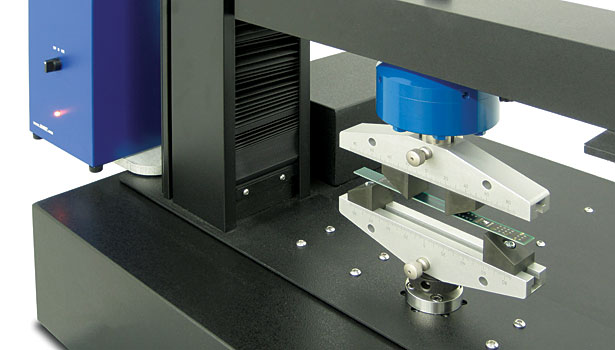

Boost Item Dependability with Our Cutting-Edge Materials Test Lab

Wiki Article

Accuracy Testing of Products for Strength and Toughness

Accuracy testing of materials for stamina and sturdiness plays an important role in different industries, including production, building, and design. This procedure entails subjecting different materials to strenuous evaluations to identify their ability to endure external forces and preserve their stability gradually.On the planet of products testing, accuracy is paramount. Researchers and designers count on exact and trustworthy information to make enlightened decisions about material option, design optimization, and item efficiency. By making use of sophisticated screening strategies and advanced devices, professionals can evaluate the strength and resilience of a wide array of products, such as steels, polymers, ceramics, and composites.

This introduction will offer insights right into the significance of precision testing, the sorts of products frequently based on screening, the vital parameters for toughness evaluation, and the methods used for resilience evaluation. It will certainly additionally highlight the applications and advantages of performing accuracy screening in different industries.

Significance of Precision Screening

Accuracy testing is an essential step in reviewing the toughness and durability of products, offering reputable and exact data for educated decision-making. When it pertains to manufacturing and building and construction markets, the top quality and performance of products play a critical function in making certain the security and long life of products and structures (materials test lab). Carrying out accuracy screening is of utmost importance to figure out whether the products fulfill the required standards and specs.By subjecting products to strenuous testing suppliers, procedures and engineers can evaluate their mechanical residential or commercial properties, such as tensile stamina, firmness, and effect resistance. This info enables them to guarantee that the materials can stand up to applied pressures and ecological conditions without failure or deterioration with time. Additionally, accuracy screening assists determine any type of prospective defects or weaknesses in the products, making it possible for makers to make needed enhancements or adjustments to enhance efficiency and integrity.

Moreover, precision screening gives measurable and unbiased data that can be made use of to contrast different products and make notified decisions concerning their suitability for specific applications. This details is especially valuable when picking products for vital components or structures where failing might have severe effects.

Kinds Of Products Subjected to Evaluating

Numerous products go through screening for stamina and sturdiness. This testing is important to make certain that the products can hold up against the demands of their desired applications and to establish their expected life expectancy. The sorts of products based on screening vary and include metals, polymers, ceramics, compounds, and construction materials.Metals, such as steel and light weight aluminum, are typically evaluated for their tensile toughness, solidity, and resistance to deterioration. materials test lab. These tests aid determine their suitability for usage in structural applications, equipment, and different industrial procedures

Ceramic products, such as porcelain and ceramic floor tiles, are examined for their compressive stamina, warm resistance, and toughness. These tests ensure that porcelains can withstand severe environments and high temperatures, making them suitable for applications in the building and construction, electric, and aerospace industries.

Compounds, which are materials made from a mix of different parts, are subjected to different tests to examine their mechanical buildings, such as toughness, effect, and rigidity resistance. Composite materials are extensively made use of in industries such as aerospace, vehicle, and sporting activities equipment production.

Construction products, consisting of asphalt, wood, and concrete, go through screening to identify their load-bearing capability, sturdiness, and resistance to weathering. These tests are critical in making sure the security and durability of bridges, structures, and roadways.

Trick Parameters for Toughness Assessment

One of the vital specifications for toughness assessment is the tensile stamina, which gauges a material's capability to withstand drawing forces without breaking or warping. Another crucial criterion is the compressive toughness, which evaluates a material's resistance to being or squashing pressed with each other. By evaluating these essential specifications, scientists and designers can accurately evaluate the stamina and longevity of products, enabling them to make informed decisions in different markets such as aerospace, vehicle, building and construction, and production.

Techniques for Resilience Assessment

Durability evaluation strategies are essential for examining the lasting efficiency and reliability of materials. These methods are critical in identifying the capability of products to hold up against numerous environmental conditions and mechanical anxieties over expanded durations of time.An additional strategy is cyclic screening, which involves subjecting materials to repeated loading and unloading cycles. This helps assess the material's tiredness resistance and its capability to stand up to repetitive anxiety without failing. By examining the stress-strain feedback of the product throughout cyclic screening, scientists can determine possible weak factors and review the material's longevity.

Furthermore, non-destructive testing techniques such as ultrasonic testing and infrared thermography can be employed to examine the inner honesty and identify any kind of issues or damages in the material. These techniques provide valuable information concerning the product's toughness without creating any type of damage to it.

Applications and Advantages of Accuracy Testing

Precision screening plays an essential role in assessing the strength and longevity of products, allowing article source researchers and designers to acquire dependable and exact data for evaluating their efficiency. The applications of precision screening are wide-ranging and can be located across numerous sectors, consisting of aerospace, vehicle, building, and production.Among the key advantages of visit our website precision screening is its ability to recognize prospective weak points or defects in products. By subjecting materials to regulated and extensive screening, any flaws or vulnerabilities can be found before they lead to tragic failures. This enables manufacturers to make essential renovations or adjustments to improve the total high quality and durability of their products.

Accuracy screening also assists in determining the ideal layout and composition of materials. By checking various variations and setups, designers can recognize the most appropriate products for details applications. This leads to enhanced effectiveness, efficiency, and cost-effectiveness in numerous industries.

Additionally, accuracy screening gives valuable data for the advancement and enhancement of products and making processes. materials test lab. It enables scientists to obtain a much deeper understanding of material behavior under various problems, resulting in the development of brand-new products with boosted find more info toughness, efficiency, and longevity features

Verdict

Finally, accuracy screening plays a critical duty in assessing the strength and resilience of materials. By subjecting numerous kinds of products to extensive testing, key parameters for toughness examination can be determined. Additionally, techniques for durability evaluation give useful insights into the efficiency and life expectancy of materials. This knowledge makes it possible for markets to make informed choices and makes sure the development of resilient and reputable items.Precision screening is a vital action in assessing the toughness and sturdiness of materials, providing precise and dependable information for educated decision-making.Various products are subjected to screening for strength and toughness. The types of materials subjected to screening are diverse and include metals, polymers, porcelains, compounds, and construction products.

By analyzing the stress-strain feedback of the material during cyclic testing, researchers can determine prospective weak factors and assess the product's longevity.

In conclusion, precision testing plays an important function in examining the toughness and sturdiness of products.

Report this wiki page